What is G-code

G-code is the generic name for plain-text language that CNC machines can understand. Manufacturers all around the world use CNC programming to control a machine to produce parts, it tells the machine where – and how – to move. Although G-code is supposed to be a universal standard, there are small differences from one machine to another. It really comes down to the capabilities of each machine. For example, the Maslow cnc control board will execute a M106 command as a Laser ON activating a pin on the board to turn the laser ON, while the same M106 command in a Marlin control board will turn the fan at full speed.

When in doubt, always refer to the documentation of your CNC machine.

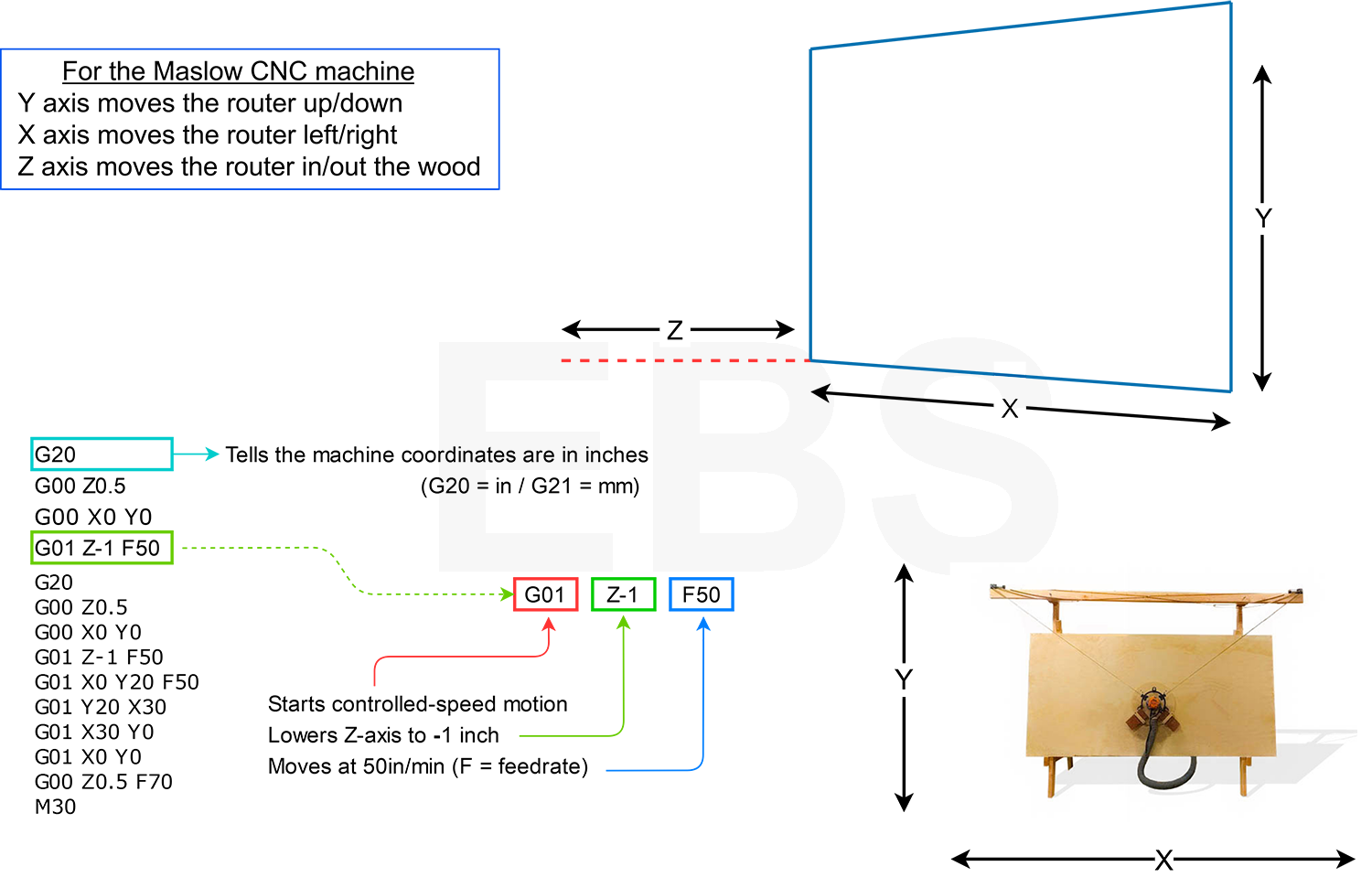

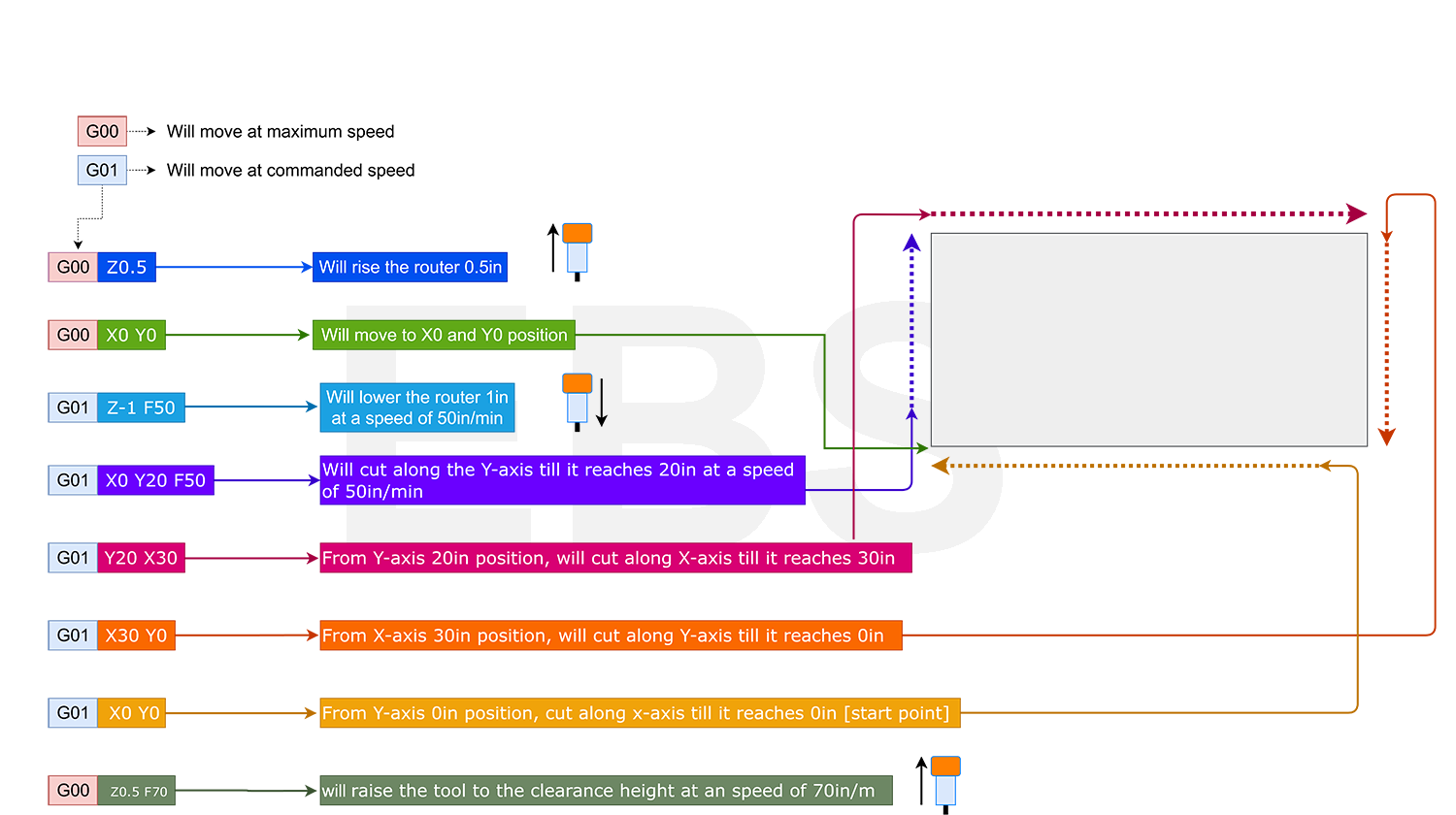

Here is an example of a G-code file that will cut a rectangle.

%

G20

G00 Z0.5

G00 X0 Y0

G01 Z-1 F50

G01 X0 Y20 F50

G01 Y20 X30

G01 X30 Y0

G01 X0 Y0

G00 Z0.5 F70

M30

%

G20

G00 Z0.5

G00 X0 Y0

G01 Z-1 F50

G01 X0 Y20 F50

G01 Y20 X30

G01 X30 Y0

G01 X0 Y0

G00 Z0.5 F70

M30

%

Let's see how it works

Now let's break it down line by line.

List of commands

While the commands are called G code, G is not the only letter used. Different letters dictate how the machine moves and numbers set the parameters.

N The N value gives the line number.

G G commands often tell the control what kind of motion is wanted

X, Y, Z These values indicate the position of the tool in three dimensions — X for horizontal, Y for vertical and Z for depth.

F F relates to how quickly the machine feeds the piece.

S S tells the machine the rpm of the spindle.

T The T tells the machine which tool to use.

M M values give miscellaneous functions or machine functions, telling the device how to act by giving on and off directions.

I, J These values indicate the incremental center of any arcs the machine makes.

R R gives the radius of arcs made by the machine.

A A values direct the tool around the x-axis.

B The number with B shows the rotational value around the y-axis. C An auxiliary axis that rotates around the z-axis gets its positional value from the C value.

D This number shows how much the system offsets the tool diameter.

L L gives the system a value to indicate repeating operations and how many times they need to loop.

P The program jumps in time or a delayed time with the P command.

G G commands often tell the control what kind of motion is wanted

X, Y, Z These values indicate the position of the tool in three dimensions — X for horizontal, Y for vertical and Z for depth.

F F relates to how quickly the machine feeds the piece.

S S tells the machine the rpm of the spindle.

T The T tells the machine which tool to use.

M M values give miscellaneous functions or machine functions, telling the device how to act by giving on and off directions.

I, J These values indicate the incremental center of any arcs the machine makes.

R R gives the radius of arcs made by the machine.

A A values direct the tool around the x-axis.

B The number with B shows the rotational value around the y-axis. C An auxiliary axis that rotates around the z-axis gets its positional value from the C value.

D This number shows how much the system offsets the tool diameter.

L L gives the system a value to indicate repeating operations and how many times they need to loop.

P The program jumps in time or a delayed time with the P command.

CODE CATEGORY FUNCTION

G00 Motion Move in a straight line at rapids speed.

G01 Motion Move in a straight line at last speed commanded by a (F)eedrate

G02 Motion Clockwise circular arc at (F)eedrate

G03 Motion Counter-clockwise circular arc at (F)eedrate

G04 Motion Dwell: Stop for a specified time. P for milliseconds X for seconds

G05 Motion Spline Definition

G06 Motion Spline Interpolation

G08 Motion Radius Mode

G09 Motion Exact stop check

G10 Compensation Programmable parameter input

G14 Coordinate Polar coordinate programming, absolute

G15 Coordinate Polar coordinate programming, relative

G16 Coordinate Definition of pole point in polar system

G17 Coordinate Select X-Y plane selection

G18 Coordinate Select X-Z plane selection

G19 Coordinate Select Y-Z plane selection

G20 Coordinate Program coordinates are inches

G21 Coordinate Program coordinates are mm

G27 Motion Reference point return check

G28 Motion Return to home position

G29 Motion Return from the reference position

G30 Motion Return to the 2nd, 3rd, and 4th reference point

G32 Canned Single-point threading, longhand style.

G40 Compensation Tool cutter compensation OFF

G41 Compensation Tool cutter compensation left

G42 Compensation Tool cutter compensation right

G43 Compensation Apply tool length compensation (plus)

G44 Compensation Apply tool length compensation (minus)

G49 Compensation Tool length compensation cancel

G50 Compensation Reset all scale factors to 1.0

G51 Compensation Turn on scale factors

G52 Coordinate Local workshift for all coordinate systems: add XYZ offsets

G53 Coordinate Machine coordinate system (cancel work offsets)

G54 Coordinate Work coordinate system (1st Workpiece)

G55 Coordinate Work coordinate system (2nd Workpiece)

G56 Coordinate Work coordinate system (3rd Workpiece)

G57 Coordinate Work coordinate system (4th Workpiece)

G58 Coordinate Work coordinate system (5th Workpiece)

G59 Coordinate Work coordinate system (6th Workpiece)

G61 Other Exact stop check mode

G62 Other Automatic corner override

G63 Other Tapping mode

G64 Other Best speed path

G65 Other Custom macro simple call

G68 Coordinate Coordinate System Rotation

G69 Coordinate Cancel Coordinate System Rotation

G73 Canned High speed drilling cycle (small retract)

G74 Canned Left hand tapping cycle

G76 Canned Fine boring cyle

G80 Canned Cancel canned cycle

G81 Canned Simple drilling cycle

G82 Canned Drilling cycle with dwell (counterboring)

G83 Canned Peck drilling cycle (full retract)

G84 Canned Tapping cycle

G85 Canned Boring canned cycle, no dwell, feed out

G86 Canned Boring canned cycle, spindle stop, rapid out

G87 Canned Back boring canned cycle

G88 Canned Boring canned cycle, spindle stop, manual out

G89 Canned Boring canned cycle, dwell, feed out

G90 Coordinate Absolute programming of XYZ (type B and C systems)

G90.1 Coordinate Absolute programming IJK (type B and C systems)

G91 Coordinate Incremental programming of XYZ (type B and C systems)

G91.1 Coordinate Incremental programming IJK (type B and C systems)

G92 Coordinate Offset coordinate system and save parameters

G92.1 Coordinate Cancel offset and zero parameters

G92.2 Coordinate Cancel offset and retain parameters

G92.3 Coordinate Offset coordinate system with saved parameters

G94 Motion Units per minute feed mode. Units in inches or mm.

G95 Motion Units per revolution feed mode. Units in inches or mm.

G96 Motion Constant surface speed

G97 Motion Cancel constant surface speed

G98 Canned Return to initial Z plane after canned cycle

G99 Canned Return to initial R plane after canned cycle

======================================================

MASLOW CNC M-codes

======================================================

M0 Program Pause / Unconditional Halt / Stop

M1 Optional Pause / Halt / Sleep

M2 End of Program

M3 Spindle ON

M4 Spindle ON

M5 Spindle OFF

M6 Tool change

M30 Program End with return to program top

M106 Laser ON

M107 Laser OFF

G00 Motion Move in a straight line at rapids speed.

G01 Motion Move in a straight line at last speed commanded by a (F)eedrate

G02 Motion Clockwise circular arc at (F)eedrate

G03 Motion Counter-clockwise circular arc at (F)eedrate

G04 Motion Dwell: Stop for a specified time. P for milliseconds X for seconds

G05 Motion Spline Definition

G06 Motion Spline Interpolation

G08 Motion Radius Mode

G09 Motion Exact stop check

G10 Compensation Programmable parameter input

G14 Coordinate Polar coordinate programming, absolute

G15 Coordinate Polar coordinate programming, relative

G16 Coordinate Definition of pole point in polar system

G17 Coordinate Select X-Y plane selection

G18 Coordinate Select X-Z plane selection

G19 Coordinate Select Y-Z plane selection

G20 Coordinate Program coordinates are inches

G21 Coordinate Program coordinates are mm

G27 Motion Reference point return check

G28 Motion Return to home position

G29 Motion Return from the reference position

G30 Motion Return to the 2nd, 3rd, and 4th reference point

G32 Canned Single-point threading, longhand style.

G40 Compensation Tool cutter compensation OFF

G41 Compensation Tool cutter compensation left

G42 Compensation Tool cutter compensation right

G43 Compensation Apply tool length compensation (plus)

G44 Compensation Apply tool length compensation (minus)

G49 Compensation Tool length compensation cancel

G50 Compensation Reset all scale factors to 1.0

G51 Compensation Turn on scale factors

G52 Coordinate Local workshift for all coordinate systems: add XYZ offsets

G53 Coordinate Machine coordinate system (cancel work offsets)

G54 Coordinate Work coordinate system (1st Workpiece)

G55 Coordinate Work coordinate system (2nd Workpiece)

G56 Coordinate Work coordinate system (3rd Workpiece)

G57 Coordinate Work coordinate system (4th Workpiece)

G58 Coordinate Work coordinate system (5th Workpiece)

G59 Coordinate Work coordinate system (6th Workpiece)

G61 Other Exact stop check mode

G62 Other Automatic corner override

G63 Other Tapping mode

G64 Other Best speed path

G65 Other Custom macro simple call

G68 Coordinate Coordinate System Rotation

G69 Coordinate Cancel Coordinate System Rotation

G73 Canned High speed drilling cycle (small retract)

G74 Canned Left hand tapping cycle

G76 Canned Fine boring cyle

G80 Canned Cancel canned cycle

G81 Canned Simple drilling cycle

G82 Canned Drilling cycle with dwell (counterboring)

G83 Canned Peck drilling cycle (full retract)

G84 Canned Tapping cycle

G85 Canned Boring canned cycle, no dwell, feed out

G86 Canned Boring canned cycle, spindle stop, rapid out

G87 Canned Back boring canned cycle

G88 Canned Boring canned cycle, spindle stop, manual out

G89 Canned Boring canned cycle, dwell, feed out

G90 Coordinate Absolute programming of XYZ (type B and C systems)

G90.1 Coordinate Absolute programming IJK (type B and C systems)

G91 Coordinate Incremental programming of XYZ (type B and C systems)

G91.1 Coordinate Incremental programming IJK (type B and C systems)

G92 Coordinate Offset coordinate system and save parameters

G92.1 Coordinate Cancel offset and zero parameters

G92.2 Coordinate Cancel offset and retain parameters

G92.3 Coordinate Offset coordinate system with saved parameters

G94 Motion Units per minute feed mode. Units in inches or mm.

G95 Motion Units per revolution feed mode. Units in inches or mm.

G96 Motion Constant surface speed

G97 Motion Cancel constant surface speed

G98 Canned Return to initial Z plane after canned cycle

G99 Canned Return to initial R plane after canned cycle

======================================================

MASLOW CNC M-codes

======================================================

M0 Program Pause / Unconditional Halt / Stop

M1 Optional Pause / Halt / Sleep

M2 End of Program

M3 Spindle ON

M4 Spindle ON

M5 Spindle OFF

M6 Tool change

M30 Program End with return to program top

M106 Laser ON

M107 Laser OFF

If you have any questions about specific Maslow CNC controller commands, don't hesitate to contact us