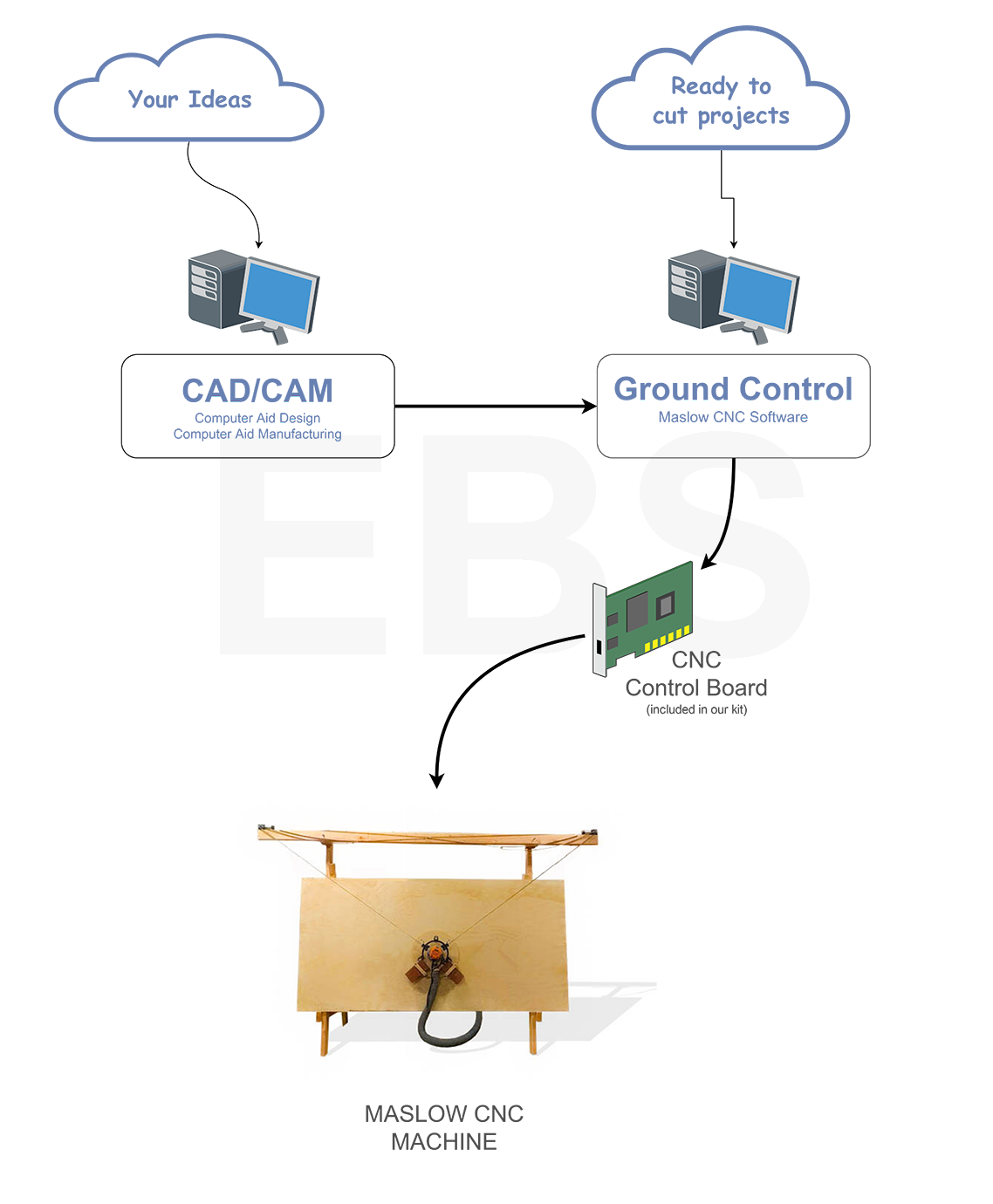

Maslow workflow

CAD/CAM

- CAD refers to the designing/drawing part of your project in a computer software (Computer Aid Design)

- CAM refers to the machining process; here is where you will choose parameters such as, bit diameter, speed (feed rate), plunge rate (z-axis speed) and so on (Computer Aid Manufacturing)

GROUND CONTROL

- MACHINE CALIBRATION

- POSITIONING YOUR PROJECT ON THE BOARD

- SEND G-CODE TO THE MACHINE

- STOP, PAUSE or QUIT a JOB

- JOG THE SLED using arrow keys

- TEST THE SYSTEM.

NOTE: Ground Control is a special purpose software created from the ground up for the Maslow CNC machine (not generic). Its main purpose is to CALIBRATE the machine and SEND G-CODE to the control board. The complex calculations of transforming g-code into electric pulses to precisely move the machine are performed in the Arduino/shield.

There is NO gain in using other modified/hacked generic open source software just to send g-code and lose the ability to properly calibrate your machine along the way. We highly recommend using GroundControl or Webcontrol.